Webinar

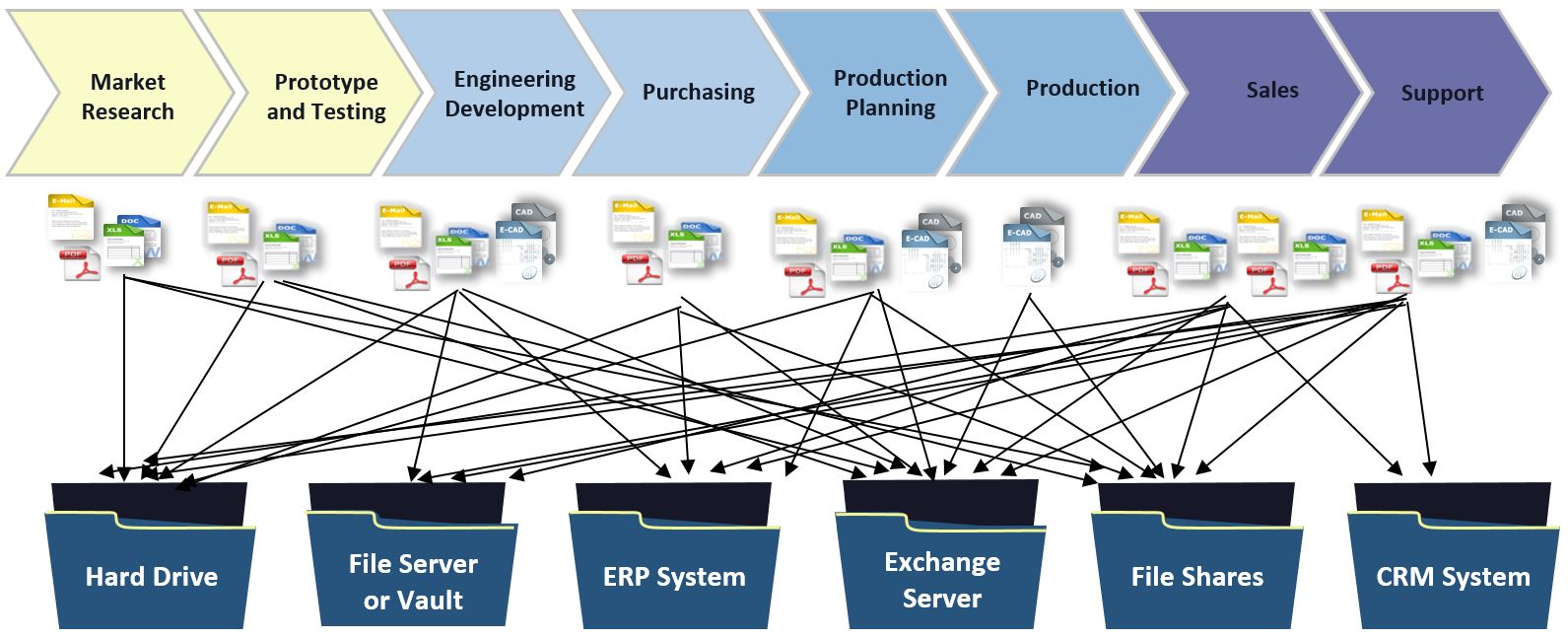

One major challenge: the complexity of product-related data and documents. Today’s products spring to life from the lifeblood of documents such as Specs and 3D CAD drawings; the data from Quality Control Reports, Engineering Change Requests, Service Records and Customer Correspondence provide a roadmap to product excellence. Yet vital as this information is, the complexity of most manufacturing environments means that your organization is probably trying to manage hundreds of different types of product-related documents. They’re probably also stored in multiple data silos, just like important data such as corresponding CAD models and drawings.

Often that looks something like this:

Repercussions and Squandered Opportunities

- The shop floor bases their work on an incorrect version of a drawing. Consequently, they build and deliver the wrong product.

- A worker manually enters the wrong BOM data, which means the wrong parts are ordered, delaying production.

- Engineers can’t view up-to-date part information when designing a product. So, they generate new part numbers of already existing parts and increase the cost of goods sold (COGS).

- When a customer asks a question or makes a request, the support team can’t find the right emails and documents to respond – increasing customer frustration.

- Departments try to share data and work from the same versions of documents, but multiple document repositories and workflow inefficiencies lead to extended delays in time to market with new products – limiting revenue.

These problems are all too common in otherwise sophisticated organizations. But there’s a simple answer to this complexity: centralizing your product-related documents and data.

Enterprise DMS for Modern Manufacturing

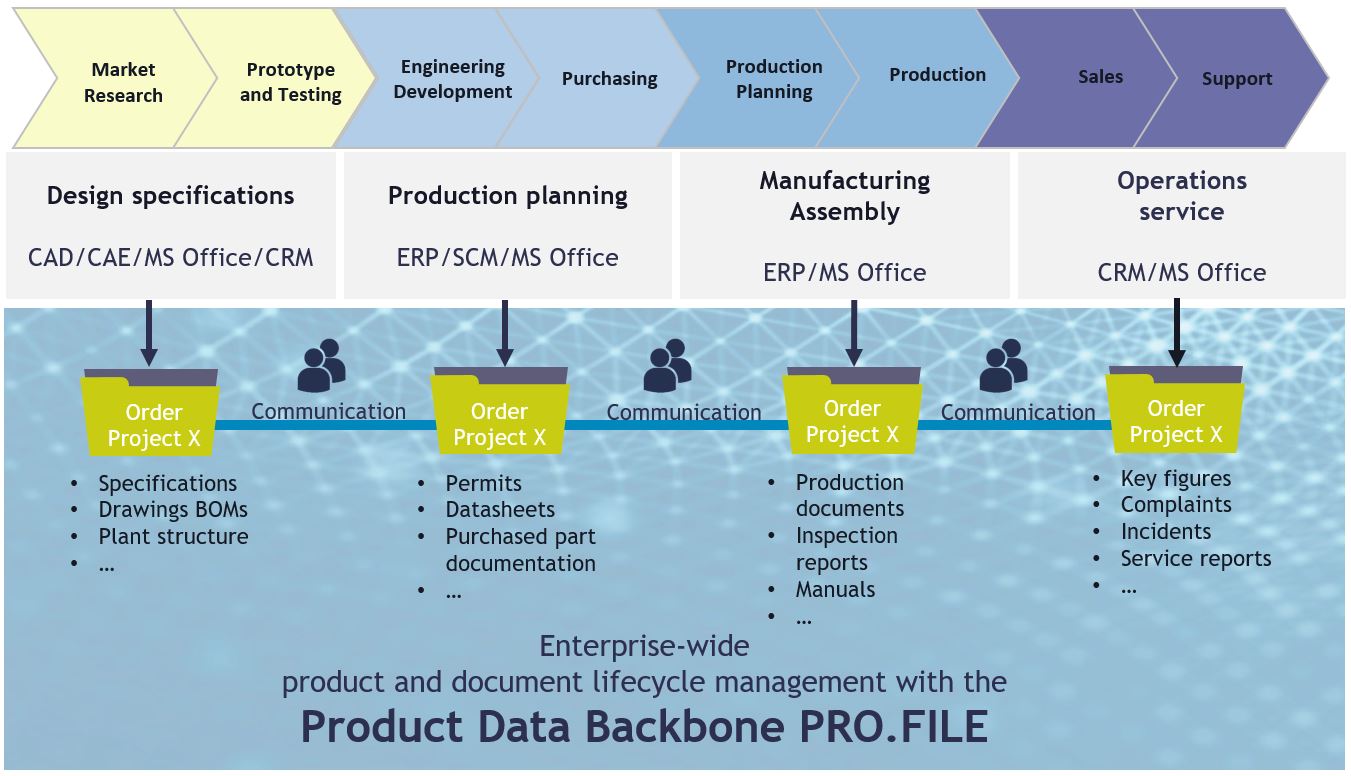

There’s one essential element to solving the above challenges: having a single source of truth for all product-related data and documents. PRO.FILE by PROCAD does this and more in multiple ways:

- All relevant information, data and documents are centralized in a unified “Digital Product Data Backbone.” Your different departments and team members work from the same, up-to-date information at all times.

- PRO.FILE then builds intelligent relationships between product data and documents and links them to your product structure.

- You can automate processes such as engineering change management, contract management or new product introduction – increasing efficiency and productivity across the whole company.

- PRO.FILE integrates with your CAD solutions and automatically sends BOM data to your ERP system.

The end result of PRO.FILE’s “Digital Product Data Backbone” is a streamlined and smoothly orchestrated system that dispels the chaos, as you can see below.