Product Data Management (PDM)

Product data consists of CAD data, ERP data, and Office documents. This makes it absolutely necessary to provide users with integrated control over the processing of this information.

Coordinate your product data and documents across system and department lines using the PRO.FILE Product Data Backbone.

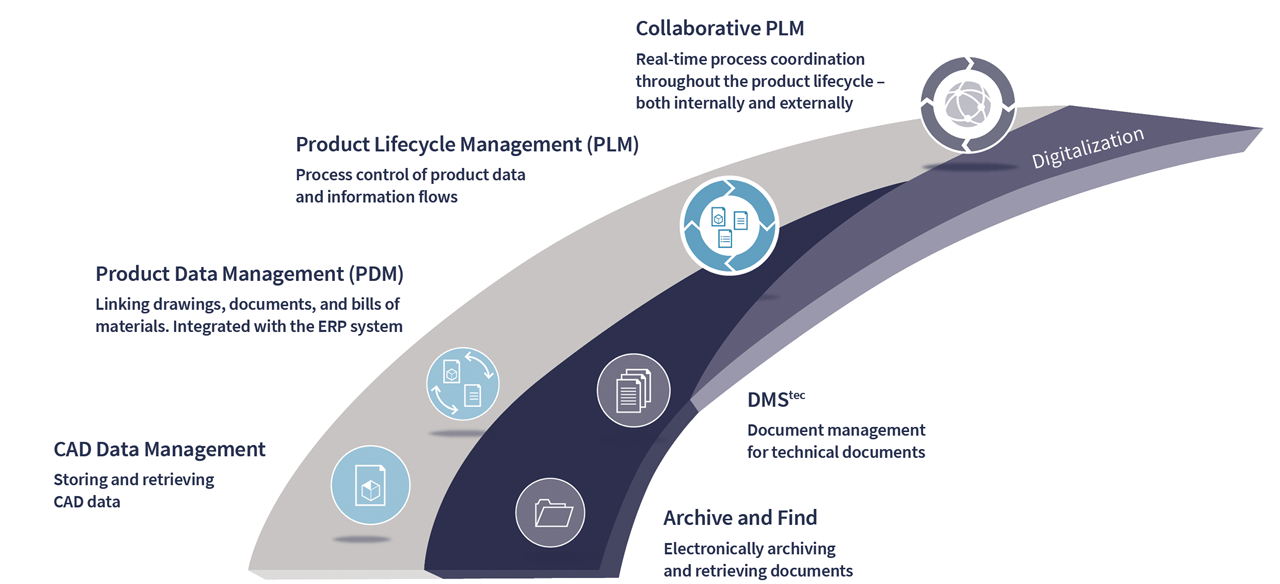

The evolution from PDM to Collaborative PLM

What PDM does for you:

- Automatically provides production with valid product information to produce from

- Leverages digitalized product information integrated from MCAD, ECAD, electronics, Office, and email sources

- Consolidates information in customer, machine and lifecycle files to give you a complete at-a-glance picture

- Keeps everything synchronized by creating an integrated information platform

Without the ability to digitally connecting drawings, documents and BOMs in combination with a bi-directional integration with ERP systems and, in a next step, to control PLM workflows and

processes, there can be no digital engineering. With the PRO.FILE digitalization platform, you can always start out with PDM and move on to your PLM processes at your own pace.

Unified product data management with multi-CAD support

With a modern PDM solution …

- you always know where an item belongs and how it is used in your company

- you are always up to date and able to retrieve information in seconds

- you can eliminate accidental overwrites of CAD data.

- you get to decide who works with what CAD data

Are you using more than one CAD system?

Accelerate your development by unifying your MCAD and ECAD data management and user experience. PRO.FILE integrates with all major CAD systems, e.g. , Autodesk Inventor, Creo, Solid Edge or Solidworks.

This calls for a PDM system that is able to seamlessly manage every single item across the enterprise.

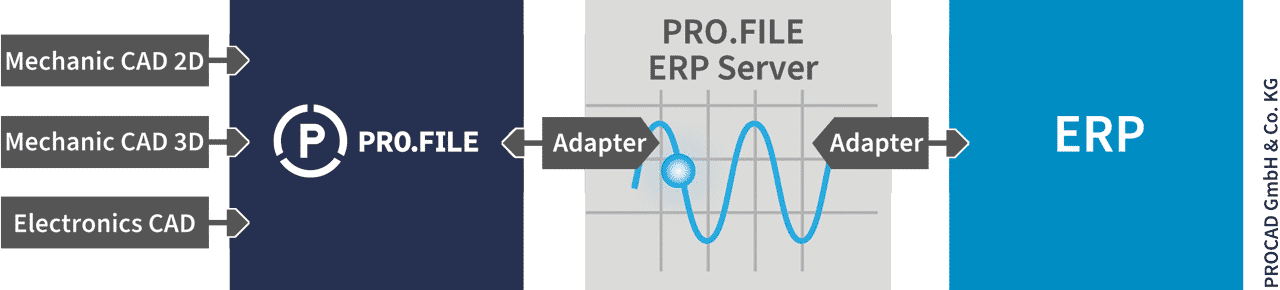

ERP integration ensures a seamless data flow and avoids transfer errors

- Gain visibility into the relationships between product data and accompanying documents:

transparent workflows, customer satisfaction, and compliance - Automatically synchronize BOMs and project structures:

no more manual entry, purchasing is provided with valid information to base their orders on

We were able to reduce the time spent maintaining part master data and bills of materials by 40-50 percent. Having the entries configured in the PDM system reduces the need to maintain lists by 30 percent.

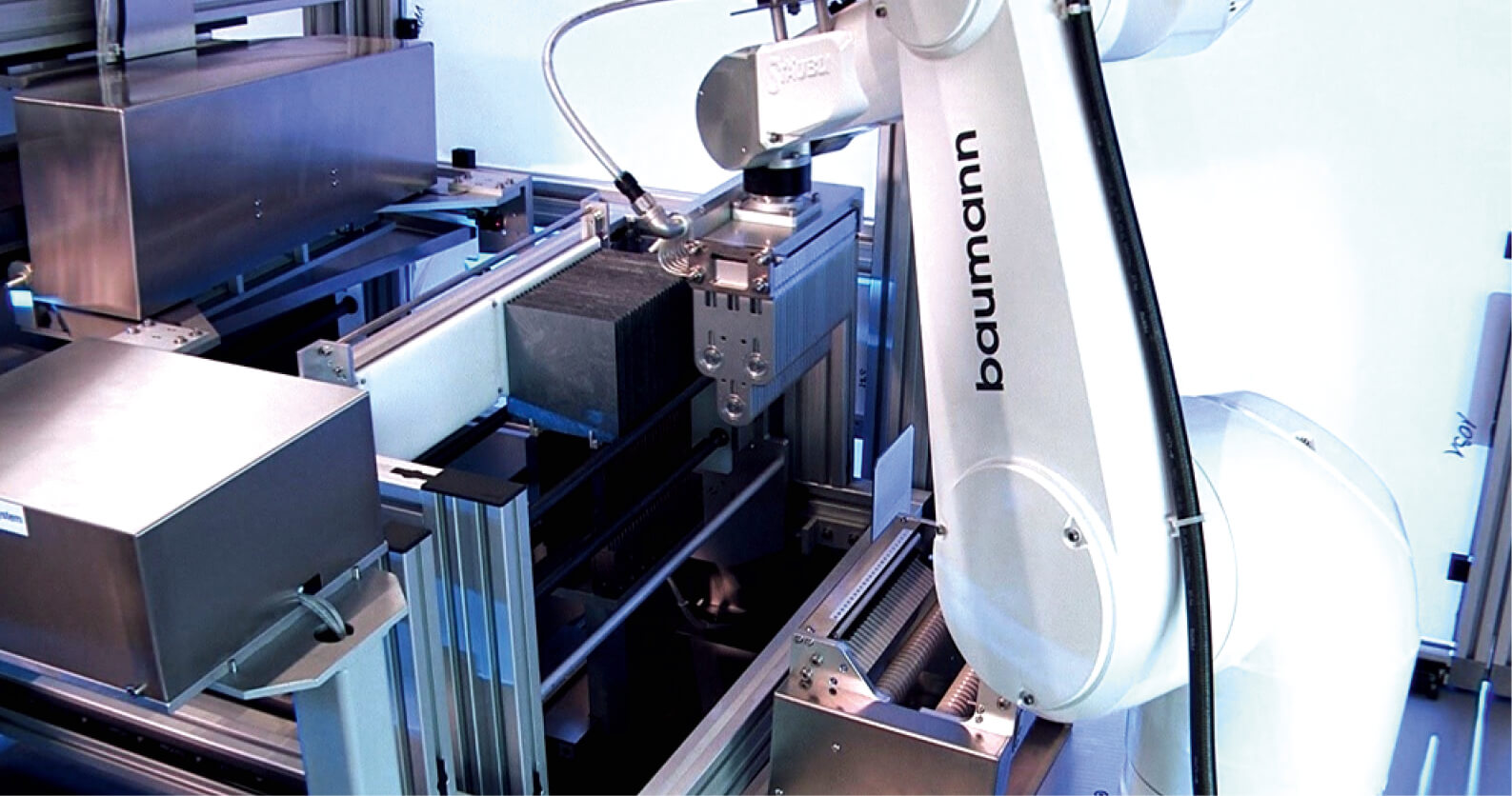

A real-life example: Baumann GmbH