PLM for product engineering

and product management

These are the main factors that drive digital engineering and product management, from product engineering all the way to operations, making advanced and forward thinking product lifecycle management (PLM) a must.

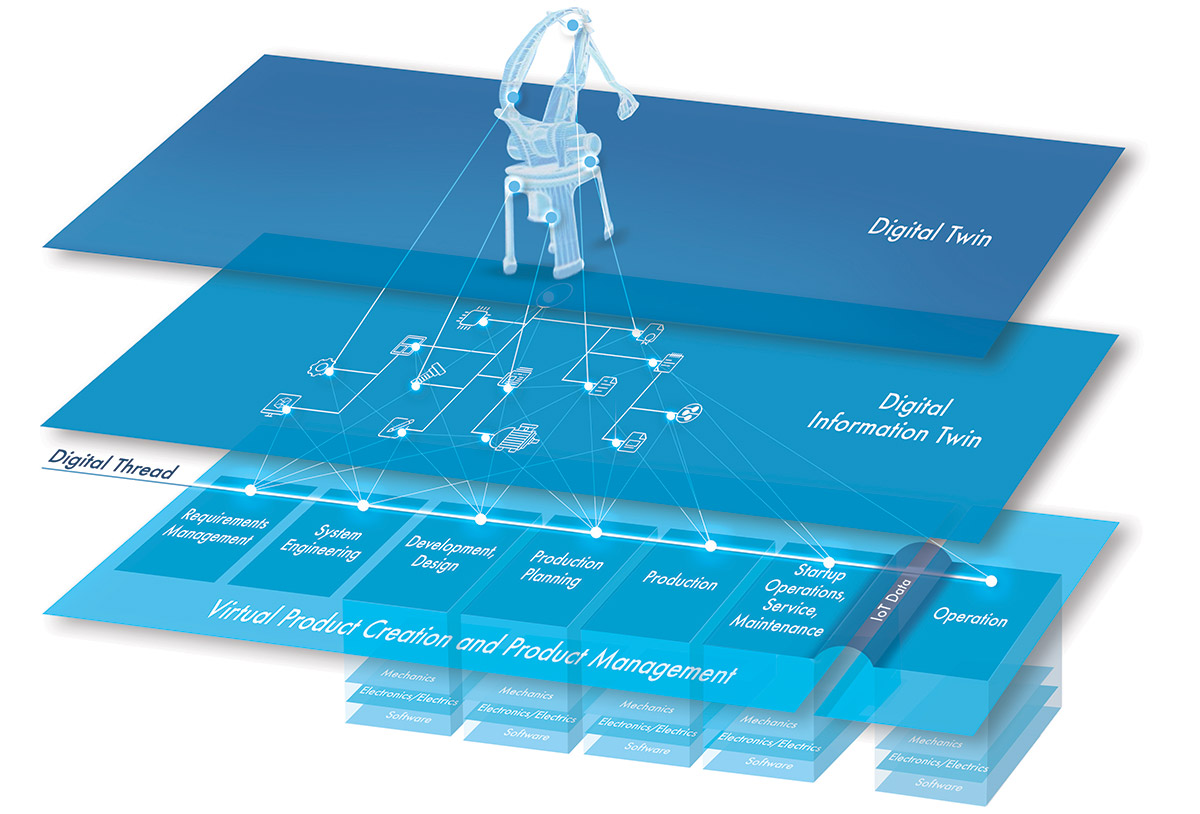

The evolution of PLM in the enterprise

Digital twin vs. digital information twin

Digital engineering and PLM

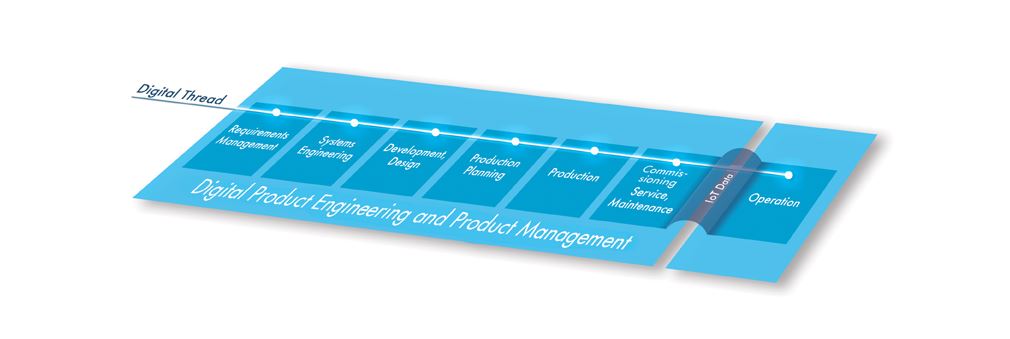

The digital thread:

benefits and implementation

Once all the information created throughout the project engineering and product management process becomes available digitally in the Product Data Backbone of a PLM system, the relationships and dependencies within PLM processes, that used to only exist in the heads of relevant employees, are now visible and clearly traceable through the system. This allows companies to, for example, draw product engineering conclusions and perform impact analyses for predictive maintenance purposes. This is what’s called the digital thread.

A real-life example: 2G Energy AG