Webinar

Karlsruhe, October 15, 2019. Secure product data storage with various approval processes and automated revisions – esmo AG’s incumbent proprietary PDM system simply was not up to the task. Consequently, in early 2018, the company replaced it with PRO.FILE. The PLM software has also helped them implement a change management process for their drawing management that relies on the PRO.FILE add-on PRO.CEED. Founded in 2001, esmo AG is part of the esmo group of companies with its global operations in various industry sectors. In November 2011, esmo AG joined Accuron Technologies Limited.

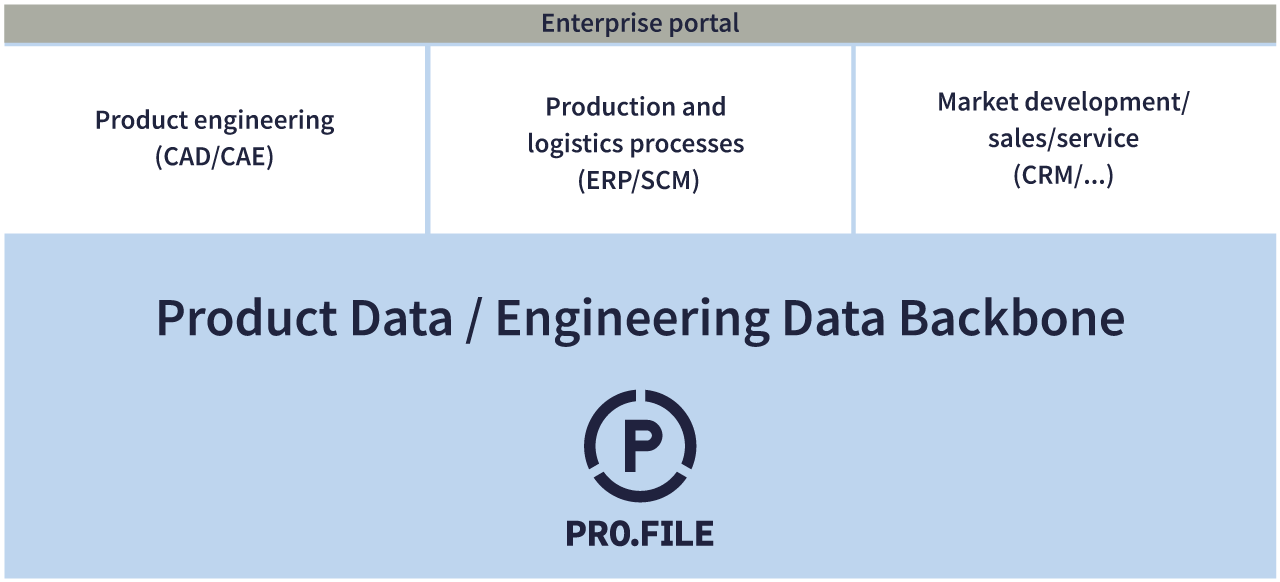

esmo AG’s designers use PRO.FILE to manage their SolidWorks data along with the data coming from their EPLAN electrical engineering software. Placed between these CAD systems and the PSIPenta ERP solution, PRO.FILE integrates these two worlds and leverages Microsoft BizTalk Server to synchronize the data. SolidWorks and EPLAN supply PRO.FILE with items and BOMs, BizTalk Server transforms them into XML files and then transfers them to PSIPenta. esmo AG worked closely with PROCAD to define the functional specifications for the PRO.FILE integration with CAD/ERP and EPLAN. For its drawing revisioning and downstream processes, esmo also worked hand in hand with PROCAD to adapt the PRO.CEED processes accordingly. esmo plans to include other processes, such as contract management, as well in order to fully leverage the power of PRO.FILE as a digitalization platform.

“It’s a huge advantage to have a PLM system like PRO.FILE that is able to manage data from any CAD system,” explains Markus Hittmann, Manager IT Worldwide at esmo AG. “You can integrate anything that creates items including any related documents.” A total of 25 mechanical designers and 4 electronic designers use the software. Overall, the company has 120 licenses for its 150 employees – surpassing even the number of PSIPenta licenses! As part of its digitalization strategy, the company is seeking to further expand PRO.FILE to make it its information backbone that can be used without requiring ERP knowledge.

Markus Hittmann: “With PRO.FILE, we were able to significantly improve the security and quality of our data and it makes the execution of manufacturing projects so much easier. We now have a very structured process; everyone knows exactly what to do with our new workflows and approvals.”

PRO.FILE is currently being rolled out across the enterprise and used as a document management system (DMStec system) to also manage the company’s business documents. Today, mechanical and electrical designers, programmers, project managers, manufacturing teams, purchasers, and sales reps alike use the system. The next step is to integrate accounting as well to streamline the processing of incoming invoices. Every piece of information related to the company’s technical projects will from now on be managed in the PLM software and maintained from within PSIPenta.