Webinar

Karlsruhe, Troisvierges (Luxembourg), 19. May 2020. Luxforge Sàrl has implemented the PRO.FILE PLM solution. PROCAD partner Cideon advises Luxembourg-based Luxforge on all things PDM and PLM and has successfully implemented the PLM system. As such, PRO.FILE complements Autodesk’s RealityCapture software along with a string of other products in the Autodesk Product Design & Manufacturing Collection (PD&MC), which Cideon had previously also installed at Luxforge.

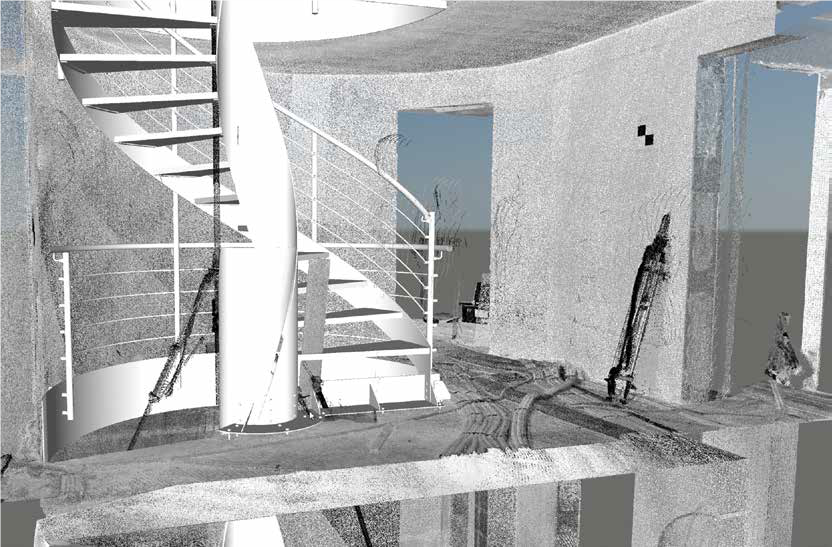

Luxforge is a leading custom metal fabricator for Luxembourg and its neighboring companies. The company specializes in the manufacturing and installation of stairways, railings, gates, balconies, and other metal constructions for private, commercial and industrial use. Headquartered in Troisvierges, in the north of Luxembourg, Luxforge supplies the Greater Region of Luxembourg, Germany, Belgium and France with tailor-made constructions.

Multi-CAD and multi-ERP capabilities put PRO.FILE ahead

At the time of the PDM/PLM implementation project, the company was still using a number of CAD systems and was also planning to implement a new ERP system. This made PRO.FILE with its multi-CAD and multi-ERP capabilities the perfect solution to accommodate the company’s goals. As the Product Data Backbone, the PLM system manages and integrates Luxforge’s product data and documents. Along with Autodesk PD&MC, it is a key enabler for the digitalization of the company’s product engineering and management processes as part of its overall digital transformation.

Within days of the implementation of PRO.FILE, Luxforge was able to use it for a first round of small orders, from measurement and costing to production planning and production control. Today, the PDM/PLM system is integral to keeping processes flowing for every single order placed with Luxforge, always supplying the latest data. The process starts with a request for an offer, which is then prepared by the costing department. If an order is placed, Luxforge appoints a project manager and defines workflows for the project. At this point the first documents are stored in PRO.FILE. After taking precise measurements on site using 3D laser scanning and gathering the customer’s requirements, the digi-physical picks up the pace. At this point, 90 % of questions have been clarified, the project is greenlighted in PRO.FILE, and the product is designed.

Time-to-installation reduced from ten to six days

It used to be that a conventional steel staircase project took around ten working days to complete. Today it is aided by the PDM/PLM system, reducing the time-to-installation to six working days. As a best-in-class company for the region, Luxforge plans to become a service provider to other metalworking shops and handicraft businesses to assist them on their digital journey. With PRO.FILE as their digitalization platform, they already have the required technical foundation in place.