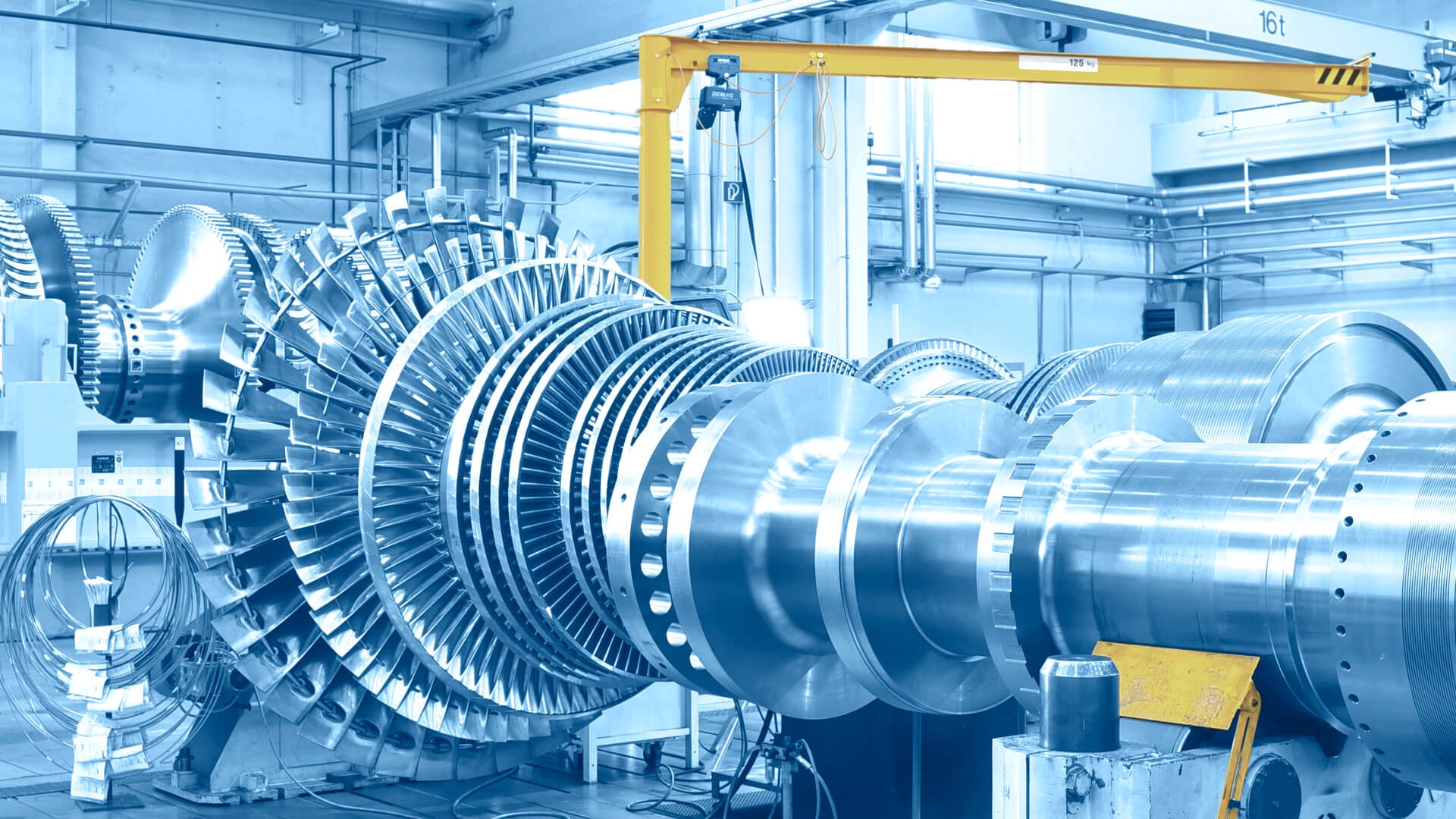

PRO.FILE keeps processes flowing

in mechanical and plant engineering

PLM/DMStec lets you …

- stay in control of variant management and reuse

- automate seamless data flows from CAD through PLM/DMStec to ERP

- feed back information (e.g. from IoT data) into product engineering

Reference customer Eugen Seitz AG

Eugen Seitz AG is a perfect example of how to implement standardized engineering change management and why it is so important to have a Product Data Backbone as a single source of truth.

- Versioned management of all product and item related data in PRO.FILE

- Faster search times, highly transparent and accountable processes

- Paperless change processes that follow a consistent workflow

Challenge & solution

The company has to comply with very strict requirements regarding approval and reporting imposed by external inspection bodies, particularly when it comes to nuclear power plants. In the past, complex change processes were completely paper based.

With the implementation of PRO.CEED as a preconfigured application package for PRO.FILE, the company was able to digitalize and simplify its change management lifecycle. This accelerated process flows and with every single step in the change process documented, user can now always track the current status in the cockpit.

What I value most about PROCAD is how quickly they respond, and even more importantly, that they never cease to innovate on their products. They listen to their customers and give them exactly what they ask for. We really appreciate that.

Reference customer Maschinenfabrik Langzauner

Maschinenfabrik Langzauner GmbH is a perfect example of how PRO.FILE was implemented as the enterprise-wide platform for product data and documents and why it is so important to have a Product Data Backbone as a single source of truth.

- PLM software integrated with SolidWorks, proALPHA ERP and eBASE

- Technical document management for all departments

- All PDM needs of typical SolidWorks users are met

Challenge & solution

Everyone involved in a project needs to be able to access design documents and other product-related information as quickly as possible. Since there was no way to automate the exchange of information between its systems, Langzauner had no choice but to work with two separate software solutions for PDM and DMS.

PRO.FILE combines the properties of Langzauner’s previous siloed PDM/PLM and DMS solutions in a single system. It now serves as the central information hub for the entire organization. It ensures that everyone involved has instant access to the most recent version.

When approaching a PDM/PLM project, you need to go beyond the mere design perspective and take a step back to look at the enterprise as whole.