Product Lifecycle Management (PLM System)

For Product Engineering and Product Management

The evolution of PLM in the enterprise

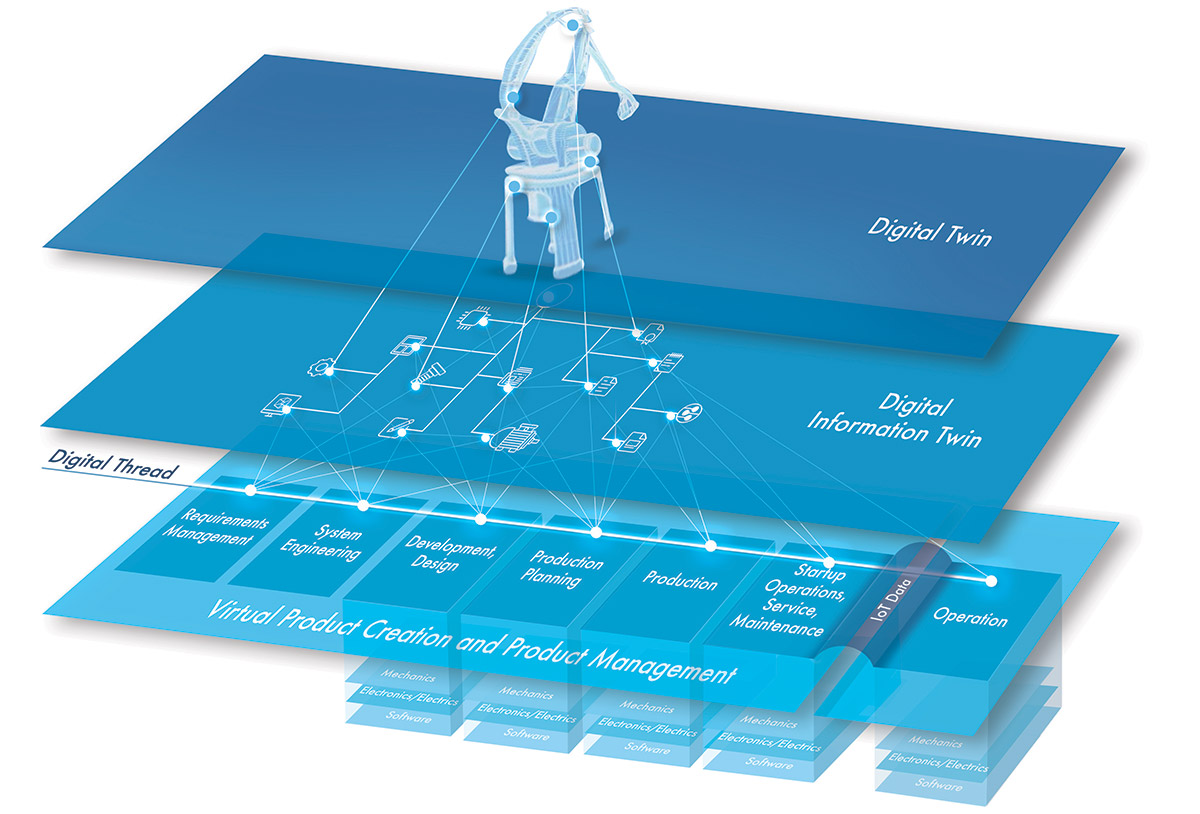

The digital information twin

A digital information twin provides the basis for the digital twin – at any point in the lifecycle from rough design to production, commissioning and operational monitoring. So, before anyone would even consider the virtual commissioning of a product, the underlying data in the PLM system must be complete and consistent.

IoT data that comes back from the field constitutes vital information from which companies can draw conclusions for their product engineering and product management. This data contributes directly to a continuous improvement process (change management), transforming the product lifecycle into a closed loop PLM process.

PLM platforms such as PRO.FILE are ideally suited to establish these types of digital information twins, which, in turn are the key to digital concepts all the way through to virtual commissioning.

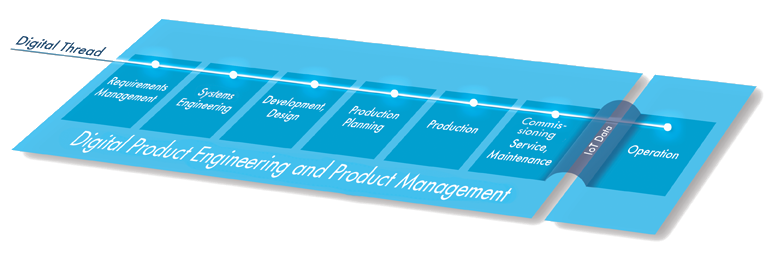

The digital thread:

benefits and implementation

Once all the information created throughout the project engineering and product management process becomes available digitally in the Product Data Backbone of a PLM system, the relationships and dependencies within PLM processes, that used to only exist in the heads of relevant employees, are now visible and clearly traceable through the system. This allows companies to draw product engineering conclusions and perform impact analyses for predictive maintenance purposes and to fine tune them to the version at hand. This is what’s called the digital thread.

The PRO.FILE digitalization platform enables your vision to engage in Digital Product Lifecycle Management

PRO.FILE serves as a Product Data Backbone and collaboration platform, along the product engineering process and across the entire product lifecycle. By combining it with the collaborative PLM platform PROOM, you can go beyond the in house departments and disciplines involved and seamlessly integrate your external partners, suppliers, and customers, giving you full control over your PLM processes.

- Gain digital dependency knowledge across the entire product lifecycle

- Establish digital information twins as the key to building digital twins

- Incorporate IoT information to drive continuous improvement

- Weave a digital thread: view and leverage digital information across the product lifecycle. Adopt modern collaboration practices to connect departments, disciplines, and external stakeholders

What Our Customers Have to Say

With PRO.FILE, 2G Energy now has a PLM solution that allows it to document even its most complex products and to control its technical and business workflows, including a number of Industry 4.0 applications. The flood of digital documents and the need to control them as part of their daily routines used to cause the employees at 2G Energy AG major headaches. Today, the company is a model for interdepartmental collaboration based on PRO.FILE.